Level

Accurately detect and control fluid levels

Industries that rely on monitoring liquid levels, such as in hydraulic reservoirs or industrial storage tanks, face significant challenges due to harsh operating conditions like extreme temperatures, pressure fluctuations, and corrosive environments. These factors can compromise the accuracy and reliability of standard level measurement and instrumentation.

Additionally, maintaining precision across multiple levels within a system, especially in complex or customized applications, often proves difficult. Regular maintenance in hard-to-access areas also leads to increased downtime and operational costs. As industries demand more accurate and resilient solutions, the complexity of managing fluid levels becomes an ongoing challenge.

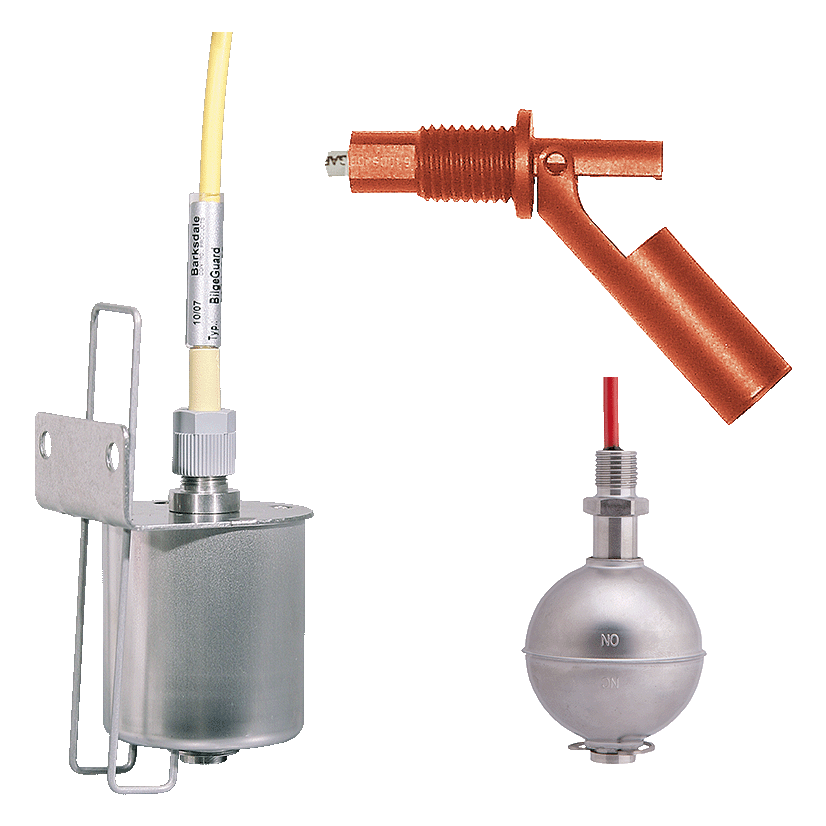

Single Level Float Switches

Single Level Float Switches made of brass, stainless steel or plastic - for the specific fluid

View Single Level Switches

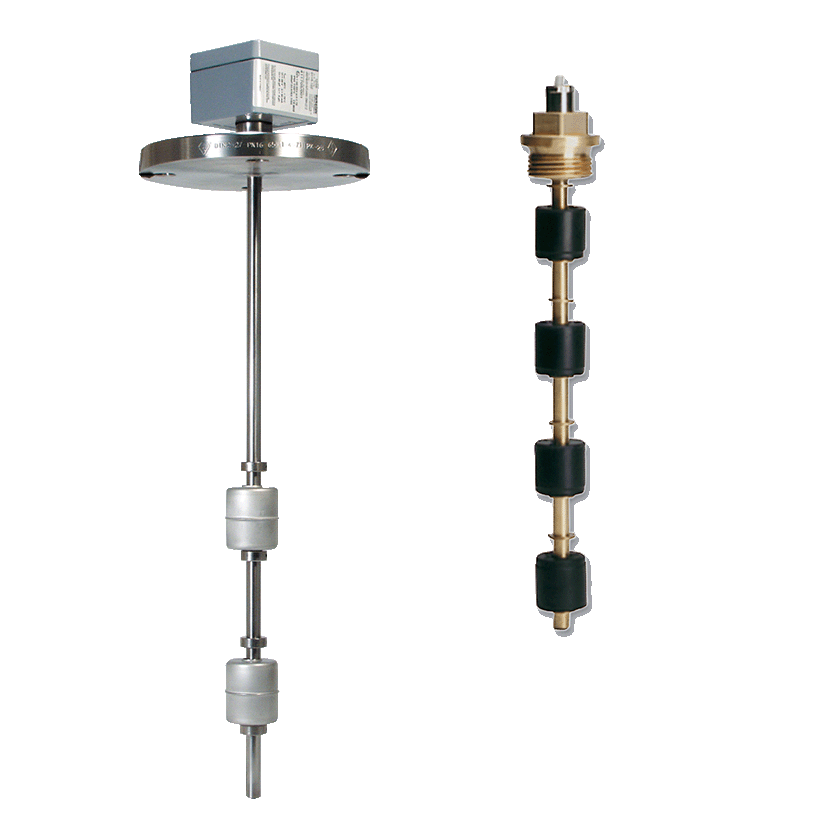

Multi Level Switches

Multi level switches, made of brass or stainless steel as standard or shipbuilding version

View Multi Level Switches

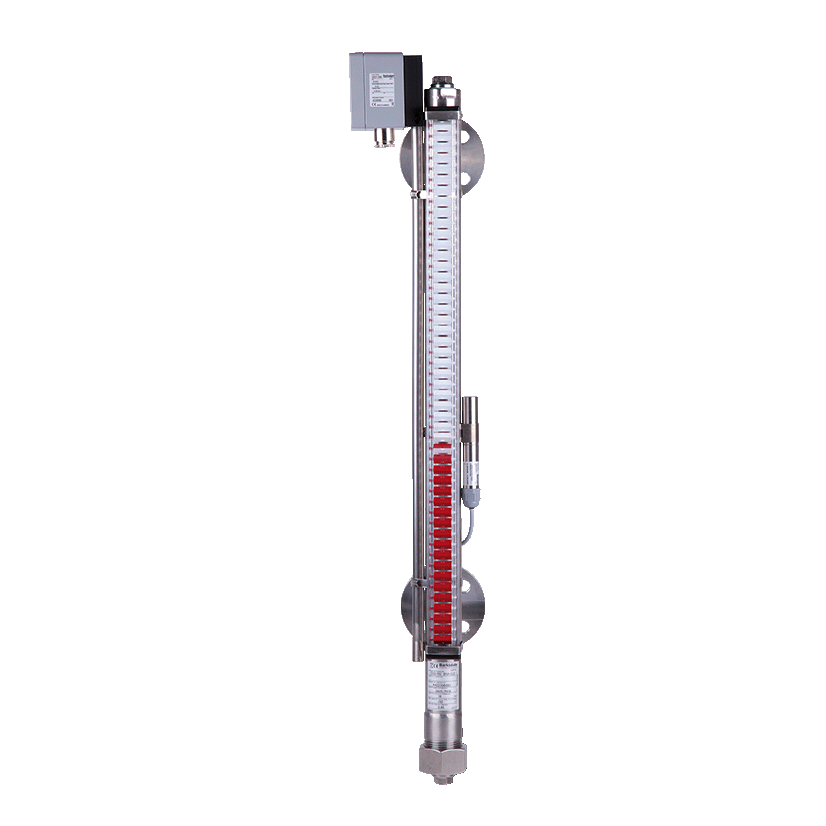

Bypass Level Indicators

Bypass Level Indicator with easy level control due to a magnetic system

View Bypass Level Indicators

Tank Level Transmitters

Sensors for indicating the level of fluids remotely in tanks

View Tank Level Transmitters

Electronic Dual Level Switches

Level control for hydraulics, lubrications system and cooling

View Electronic Dual Level SwitchesFrequently Asked Questions

Find answers to common questions below