Hydraulic power units (HPUs) are the heart of fluid-powered systems, and at the core of every HPU is the reservoir-responsible for holding and regulating hydrulic fluid. Maintaining proper fluid level and temerature inside this reservoir is essential to protect equipment, maximize performance, and prevent costly downtime. As industries look for more efficient, reliable, and compact sensing solutions, Barksdale's multi-level and integrated level-temperature switches have become a trusted standard for reservior monitoring.

Why Reservoir Monitoring Matters

When fluid levels or temperatures fall outside the optimal range, HPUs face serious risks:

- High temperature leads to fluid degradation, seal damage, and reduced lubrication.

Low fluid level can cause pump damage and cavitation, which erodes metal surfaces and deteriorates performance.

To mitigate these risks, many manufacturers rely on top‑mounted mechanical float switches—but modern designs like Barksdale’s take monitoring far beyond the basics.

The Barksdale Advantage: Multi‑Level & Integrated Monitoring

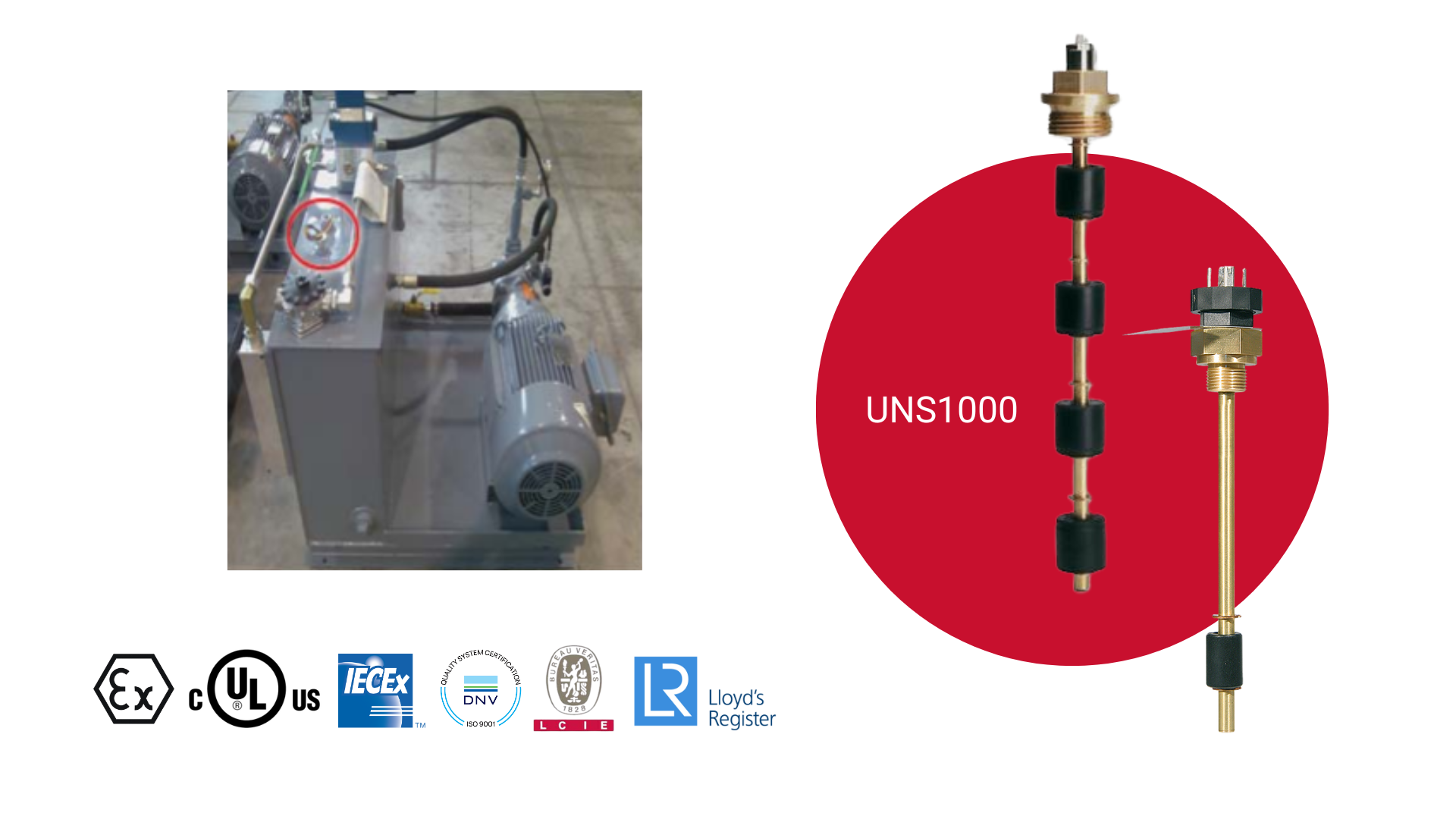

UNS1000 Multi‑Level & Temperature Switch

The UNS1000 is a versatile, highly configurable multi‑stage level switch capable of monitoring up to five independent switch points within a single compact assembly.

Key Benefits

-

Up to 5 switch points for multi‑level monitoring

-

Integrated temperature switch option, eliminating additional taps and wiring

-

Hermetically sealed reed switches, ideal for high‑viscosity hydraulic fluids

-

DIN-style connector (IP67) for moisture‑resistant, industrial operation

-

Available in brass or stainless steel with multiple mounting and connection options

In real‑world use, switching to the UNS1000 has enabled customers to eliminate junction boxes and conduit connections, reducing installation complexity, leakage points, and overall cost.

Where It’s Used

-

Hydraulic power units

-

Storage tanks

-

Sump systems

-

Solvent recovery equipment

-

Lube oil consoles